As part of the annual maintenance shutdown of a paper production facility, our team successfully carried out the renovation of a heat exchanger dating back to 1953. This project combined technical expertise, respect for the original design, and optimization of customer equipment availability.

A Historic Heat Exchanger Fully Restored

The heat exchanger, used for condensation within a papermaking process, was entirely transported to our workshop for a complete refurbishment of its tube bundle. Despite its age, the unit needed to retain its original thermal performance, essential for maintaining process stability.

Before :

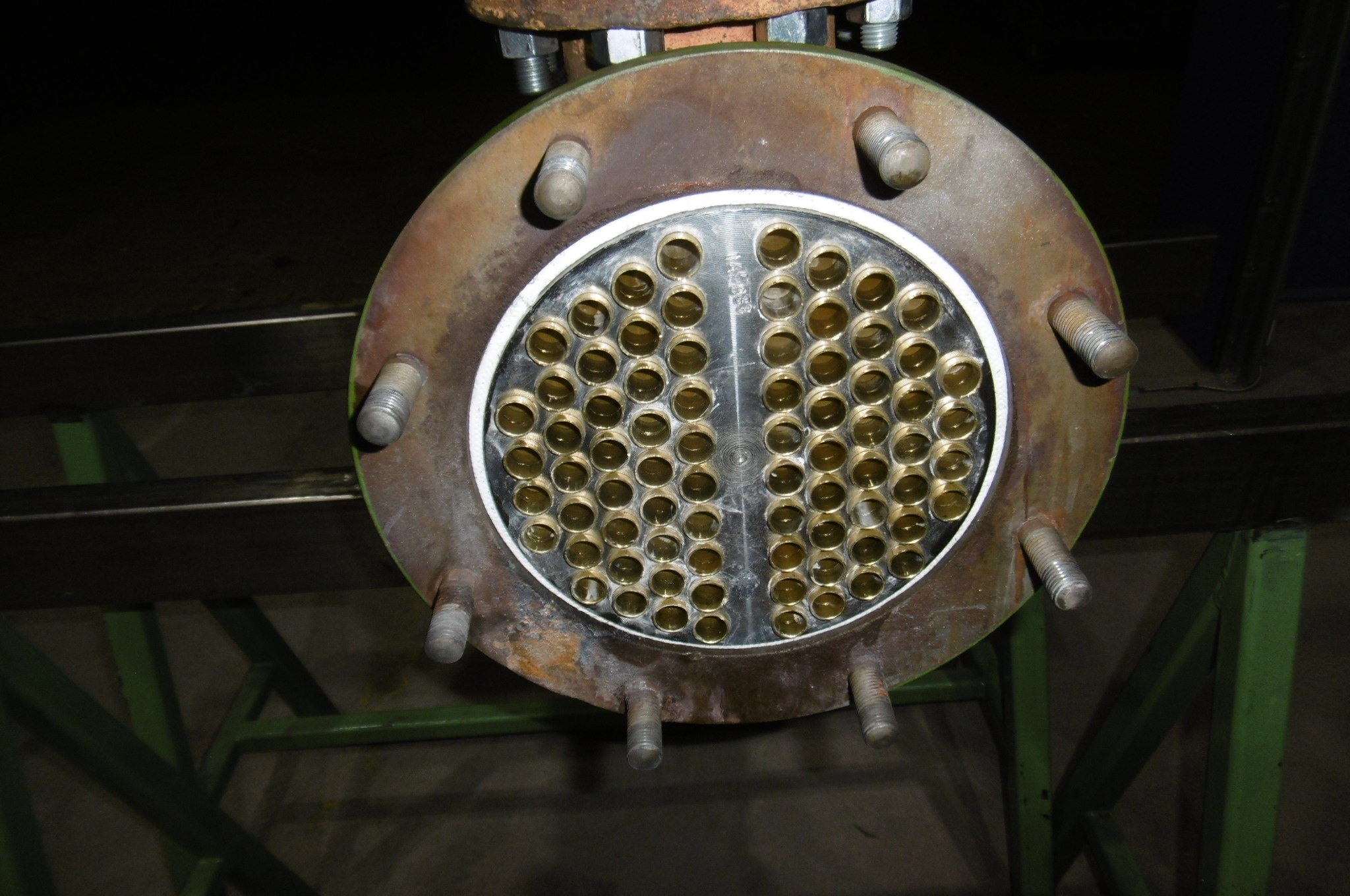

After:

Key steps in the heat exchanger repair:

- Complete disassembly of the condenser in our workshop

- Full reconstruction of the tube bundle, strictly identical to the original

- Reproduction of the tube layout and baffle configuration based on precise measurements

- Hydraulic test and leak test to ensure tightness and reliability

- Reassembly of the bundle inside its original shell

All operations were planned and completed during the plant’s maintenance window, ensuring zero impact on production.

A Bundle Designed to Match the Original Layout and Thermal Constraints

To ensure perfect compatibility with the existing installation, the tube bundle was rebuilt strictly identical to the original.

The tubes were manufactured from CuZn20Al2, an aluminium brass alloy highly resistant to corrosion and commonly used in refrigeration and heat exchange applications (copper–zinc–aluminium family). This material provides excellent mechanical strength and good thermal conductivity.

Key technical features:

- Tubes in CuZn20Al2

- Tube expansion (dudgeoning) into the tube sheet

- Preservation of the original baffle arrangement to maintain identical flow regime and thermal performance

A Measurement Process to Accurately Reproduce the Bundle and Its Components

Before any renovation work on the condenser, our team carried out a complete measurement campaign directly on the original tube bundle. All critical dimensions were recorded to recover the original manufacturing data: centre distances, required tube length, tube sheet geometry, as well as the complete tube routing. The internal baffles were also measured point by point to reproduce their geometry and quantity, ensuring identical thermal behaviour.

These measurements allowed us to produce a detailed set of drawings and a full parts list, essential for manufacturing and sourcing all components of the replacement bundle. Thanks to this rigorous approach, every new part fits perfectly into the original shell, ensuring a reliable and long-lasting renovation.

A Renovation Project Demonstrating Our Commitment

- Preserving existing industrial assets, even on ageing equipment

- Ensuring production continuity through optimized planning

- Delivering thermal performance fully compliant with the original design

This 1953 heat exchanger is now back in service with a brand-new, tested, certified tube bundle, ready to meet the demands of the papermaking industry.

OELTECHNIK France can repair or renew / refurbish many tubular heat exchangers or condensers.