All units are designed and fabricated to relevant required pipeline and vessel design codes including:

- ASME U Stamp Division 1 & 2

- ASME VIII

- NACE

- BS 5500

- ASME B31.3, B31.4, B31.8

PIG LAUNCHER & RECEIVER SKID - LIBREVILLE PROJECT

Zone 1 – Group IIA T3

Design pressure 140 barg

Diameter 12’’ x 10’’

Construction according to ASME B31.4

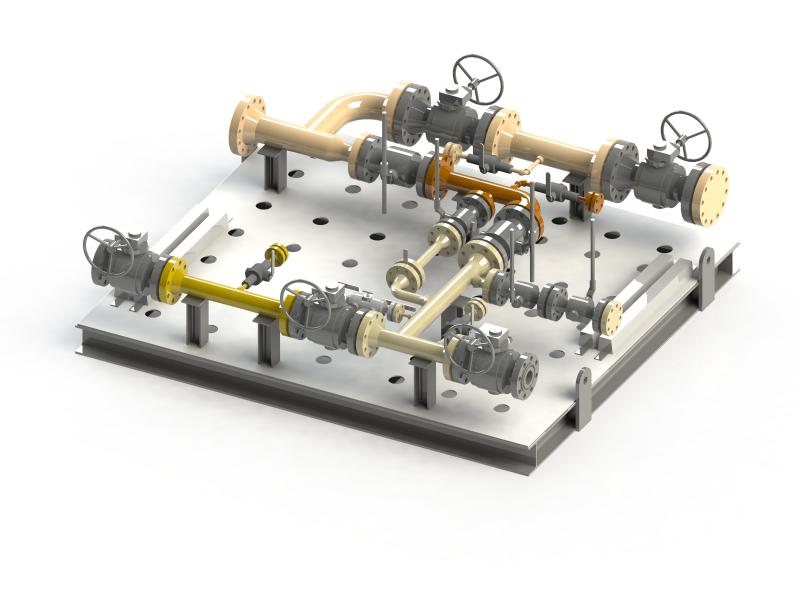

SUBMARINE SKID - LIMANDE PROJECT

Immerged under sea water, 23 meters deep

Construction according to ASME B31.3

Base plate perfored to allow immersion

Minimum design temperature : -20 °C

SEAL GAS CONDITIONING SKID - CHEVRON WHEATSTONE PROJECT

Design pressure 15,200 kPa g (152 bar g)

Design temperature 0 / 150°C

Duplex materials, Grayloc fittings

NDE including PMI, Radiography Dye, Penetrant Test

NACE MR0175

CHEMICAL INJECTION SKID - EOV DEVELOPMENT PROJECT

Dimensions 4,000 x 2,500 mm

2 atmospheric tanks on the same skid

Scavenger pump flow 12 l/H

Design conditions 5 bar g / 60 °C

GLOBAL CHARACTERISTICS

Design, manufacturing, inspection according to codes, rules and customer specifications

•Materials stainless steel (304L, 316L, 321, …), low temperature carbon steel, duplex

•Electric wiring according to european and international rules

•Painting

•Pressure range from 1 to 20 bar for lubrication and until 250 bar for regulation, seal oil, or hydrojacking

•Design temperature according to site conditions and process requirements

•Atex

•NACE MR01/75

•Fabrication according to Certification Mark U-Designator, PED 2014/68/UE, TRCU, …

-

Manufacture of a Stainless Steel 304/304L Lubrication Oil Skid

OELTECHNIK-France, a specialist in the design and manufacture of custom industrial skids, has made the design and production of a lubrication oil skid intended for an industrial installation in Taiwan.

This international project highlights our expertise in mechanical engineering and our ability to meet the most stringent technical and quality requirements.